Thermal duab rau fiber optic kev lag luam

Infrared thermal lub koob yees duab tau dav siv, thiab kev lag luam fiber ntau optic kuj tseem cuam tshuam nrog infraredthermal duab.

Fiber laser muaj qhov zoo ntawm cov nqaj zoo, siab zog ceev, siab electro-optical conversion efficiency, zoo tshav kub dissipation, compact qauv, txij nkawm-dawb, hloov tau yooj yim kis tau tus mob, thiab tau dhau los ua lub ntsiab kev taw qhia ntawm laser technology kev loj hlob thiab lub lub ntsiab quab yuam ntawm kev thov. Tag nrho cov electro-optic efficiency ntawm fiber ntau laser yog li ntawm 30% mus rau 35%, thiab feem ntau ntawm lub zog poob nyob rau hauv daim ntawv ntawm tshav kub.

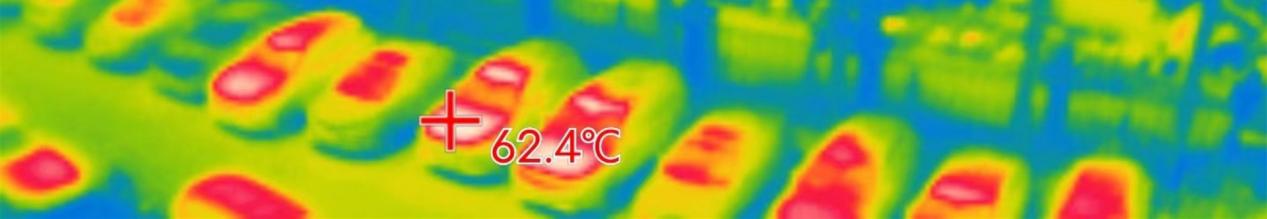

Yog li ntawd, kev tswj qhov kub thiab txias thaum lub sijhawm ua haujlwm ntawm lub laser ncaj qha txiav txim siab qhov zoo thiab kev pabcuam lub neej ntawm lub laser. Txoj kev ntsuas qhov ntsuas kub ib txwm siv yuav rhuav tshem cov qauv ntawm lub cev laser, thiab qhov ntsuas qhov ntsuas kub ib leeg tsis tuaj yeem ntsuas qhov ntsuas kub kom raug. Kev siv cov infraredlub koob yees duab thermaltxhawm rau txheeb xyuas qhov kub ntawm cov khoom siv kho qhov muag, tshwj xeeb tshaj yog cov fusion pob qij txha ntawm optical fibers, thaum lub sij hawm tsim cov txheej txheem ntawm optical fibers tuaj yeem lav qhov kev txhim kho thiab kev tswj xyuas zoo ntawm cov khoom siv fiber ntau. Thaum lub sij hawm tsim khoom, qhov kub ntawm lub twj tso kua mis qhov chaw, combiner, pigtail, thiab lwm yam yuav tsum tau ntsuas los xyuas kom meej cov khoom zoo.

Thermal imaging ntsuas kub ntawm daim ntawv thov sab kuj siv tau rau kev ntsuas kub hauv laser vuam, laser cladding thiab lwm yam scenarios.

Qhov tshwj xeeb zoo ntawm infrared thermal lub koob yees duab siv rau fiber ntau laser nrhiav tau:

1. Thermal koob yees duabmuaj cov yam ntxwv ntawm qhov ntev-ntev, tsis sib cuag thiab loj-qhov ntsuas kub ntsuas.

2. Kev ntsuas qhov kub thiab txias software, uas tuaj yeem xaiv qhov ntsuas kub ntawm qhov ntsuas kub, tuaj yeem tau txais thiab sau cov ntsuas kub siab tshaj plaws, thiab txhim kho qhov kev ntsuas ntsuas.

3. Qhov ntsuas kub ntawm qhov ntsuas kub, qhov ntsuas qhov ntsuas ruaj khov, thiab ntau qhov ntsuas kub tuaj yeem teeb tsa kom paub cov ntaub ntawv tsis siv neeg sau thiab nkhaus tsim.

4. Txhawb ntau hom kev ceeb toom kub dhau, txiav txim siab qhov txawv txav raws li cov nqi teev tseg, thiab tuaj yeem tsim cov ntaub ntawv qhia.

5. Txhawb nqa kev txhim kho theem nrab thiab kev pabcuam kev ua haujlwm, muab ntau lub platform SDK, thiab pab txhawb kev sib koom ua ke thiab tsim cov khoom siv automation.

Nyob rau hauv cov txheej txheem ntawm high-power fiber lasers, tej zaum yuav muaj optical discontinuities thiab tsis xws luag ntawm ib tug tej yam me me nyob rau hauv lub fiber fusion pob qij txha. Cov teeb meem loj heev yuav ua rau cov cua kub tsis zoo ntawm cov pob qij txha fiber ntau, ua rau lub laser puas lossis kub kub. Yog li, kev ntsuas kub ntawm fiber ntau fusion splicing pob qij txha yog ib qho tseem ceeb txuas hauv kev tsim cov txheej txheem ntawm fiber ntau lasers. Kev ntsuas kub ntawm cov fiber ntau splicing point tuaj yeem paub tau los ntawm kev siv lub koob yees duab thermal, thiaj li txiav txim siab seb qhov zoo ntawm qhov ntsuas fiber ntau splicing point puas tsim nyog thiab txhim kho cov khoom zoo.

Kev siv onlinelub koob yees duab thermalintegrated rau hauv cov khoom siv automation tuaj yeem kuaj qhov kub ntawm cov fibers kho qhov muag kom ruaj khov thiab ceev ceev kom txhim kho kev tsim khoom.

Post lub sij hawm: Feb-16-2023